The Smart Factory project is not a small or quick-win project. Organizations must invest a lot of money and team effort. The implementation timeline is between 2 and 3 years, and the ROI is typically 2 to 3 years after implementation.

This is an exclusive article series conducted by the Editor Team of CIO News with Subhash Singh Punjabi, CISO & Head Enterprise Architecture at Deepak fertilisers and Petrochemicals corporation Ltd.

Today, smart days Smart Factory implementation is not a choice, but it is mandatory for all businesses to survive and be competitive in the market.

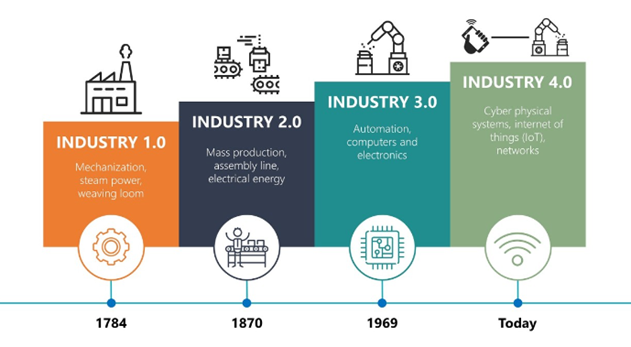

Many of the organizations have started their journey toward Industry 4.0 implementation to make their factories future-ready, or SMART.

The Smart Factory project is not a small or quick-win project. Organizations must invest a lot of money and team effort. The implementation timeline is between 2 and 3 years, and the ROI is typically 2 to 3 years after implementation.

Let’s see what challenges factories are facing without Industry 4.0.

Typical challenges in industry are divided into five main areas as follows:

Assets:

- Wide variety of legacy assets, difficult to maintain, reduce asset reliability

- Fading out OEM support leads to a higher breakdown maintenance time.

- Multiple siloed control systems and difficult system maintenance

Data:

- Manual data collection from DCS, PLC, SCADA, field devices, etc. requires a higher nonproductive effort.

- Manual data entry by multiple teams in multiple reports due to data duplicity

- Limited data storage and difficult retrieval lead to a loss of data and analysis opportunity.

Process:

- Production reporting and accounting are manual and time-consuming.

- Process optimization and troubleshooting are people-driven.

- Field work involves paper based, manual work allocation, execution, and traceability.

Connectivity:

- Non-digital equipment, manual monitoring, delayed visibility, and lack of timely alert

- OPC non-complaint equipment, non-portability of data, data entry in log sheets and logbooks

- Siloed plant control systems have limited visibility and lack of online coordinated operations.

People:

- Delayed access to information leads to delayed decision-making.

- Tribal knowledge is highly dependent on individuals.

- High attrition trend due to lack of ownership, repeated training, and loss of efficiency

All are looking to resolve the above challenges by implementing Industry 4.0.

In my view, the recommended approach for the same is in three phases, as follows:

Reimagine and Focus: Create an organization-wide holistic smart factory roadmap and vision.

- Validate the maturity and gap assessment of the current state.

- The involvement of top management and all-level employees is a must in this exercise.

- Do critical position Persona Study: Human in Loop

- Do an art of possible workshops involving all the stakeholders. Candidates use case identification and prioritize the initiative using MoSCoW.

- Finalising roadmap, including the business case, for 3 to 5 years.

Design and Blueprint

- Define Solution Charter

- RFP Creation

- Technology/vendor evaluation and selection

- Architecture design

- Vendor onboarding for POC

- Check functional fitment.

- Phase-wise “quick win” use case detailing and implementation in one plant

Deliver and Run

-

- Solution: modify or build.

- Value tracking and KPI ownership

- Agile implementation

- SIT and UAT

- Training, development, and user adoption

- Go live and hyper-care.

- Rolling over to multiple plants

The major things to concentrate on for the success of the project are as follows:

- Leadership, Business Governance, and Funding

- Result management office, change management, and adoption.

- Cross-functional solution delivery teams (design authority)

- Data governance and data quality in all 3 phases.

- Solution Architecture, Technology Architecture, Technology Governance, and Information Security

Also read: The Road Ahead: Predictions for the Future Evolution of Artificial Intelligence

Do Follow: CIO News LinkedIn Account | CIO News Facebook | CIO News Youtube | CIO News Twitter

About us:

CIO News, a proprietary of Mercadeo, produces award-winning content and resources for IT leaders across any industry through print articles and recorded video interviews on topics in the technology sector such as Digital Transformation, Artificial Intelligence (AI), Machine Learning (ML), Cloud, Robotics, Cyber-security, Data, Analytics, SOC, SASE, among other technology topics.